Here you’ll find a collection of things that I do, make, say and think. A collection of projects I publshare on other sites online. Including; custom built and designed guitar or Hi-Fi amplifiers and effects, custom PC servers, and rescued, upcycled hardware. Simply a central place to collect what I’m doing with some of my a creative rest at any given time.

If you are in search for my professional information go to >JohannesJohansson.com<

For multiple ways to contact me this >linktree< makes it easy.

Categories

- DIY (24)

- DIY Audio (13)

- DIY Computation (7)

- DIY Misc (5)

- Uncategorized (1)

Random Posts

-

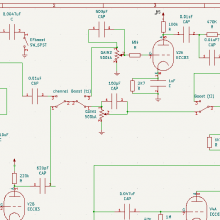

High gain SLO/Ubershall: 1 Intro

The machine, this is the main amp I play and the platform I most try to optimize. Origins in Sloclone, It can be switched between […]

-

Restomod Car: 2 Brakes and Suspension

Completely changing the suspension and brakes with oversized parts on this little car can make for a very fun ride and good companion to a […]

-

Homelab: 4 Family & apartment friendly server cabinet

Finding ways to live with an interest in computers can be a challenge. That is having half a dozen computers running 24/7 is not something […]

-

Splitter pedal: Two guitar amps at once

Splitting the output of your guitar/pedalboard to two separate Guitar Amps is one of the most powerful way in shaping your tone and ‘broaden’ the […]

-

Dumble Overdrive Special: 2 Headshell

Head, strange word for this but is what it’s called, a head being the amplifier, presumably sitting on the ‘body’ represented by the stacks of […]

PC water cooling: Maintenance

When watercooling a computer the goal is lower temperature and/or better noise to performance ratio, while also allowing for much smaller footprint with quite high end parts. However, maintenance and special care is a must when housing electronics and water together. In all it is another interesting challenge, especially when building without chassis and parts actually meant to work together.

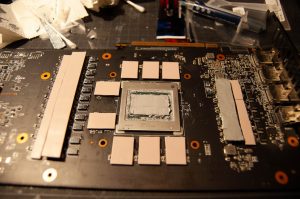

The chassis used here has seen multiple builds, all using micro-ATX motherboards while it only supposes to fit ITX-sized ones. Next as it does not support any radiators three of those have been fitted inside and outside to be able to cool a 12core CPU, a 280wattage GPU (6800xt) and the motherboard VRM, all serious heat generators on their own. But over time no matter how well the loop has been taken care of, growth will occur, if lucky some green algea minor corrosion cutting into the components. Necessitating this cleanup was a increasing temperature on the GPU die forcing the graphics card to self-downclock. A not unexpected event after some 20 months running since last clean and on the whole a 3 plus years old loop having seen many upgrades most fittings and radiators having stayed the same.

When looking at the blocks there are quite clogged parts, the GPU generally filled, the CPU had some very solid parts right in the ‘jet plate’ splitting the flow of water over the fins (see the rice-grain sized piece, that was a line across the centre).

Cleaning first with some soap and water, scrubbing with some isoproyl alcohol and chemically pure petrol does clean as much as possible without stripping the metal plating or tarnishing. Putting things together flushing the loop first with citric acid with then bicarbonate soda, both mixed in water, it gently cleans the tubing and fittings, and restore the loop Ph levels with soda at the end.

Filling the loop with good quality water I add a biocide (Benzalkonium chloride) to slow down any algea growth, as well as an anti corrosion addative, as nickelplating copper and brass are present, some corrosion will occur. This is also a good time to swap some fittings in, changing two suspect ones showing some signs of leaking. These old alpha cool ones have been nice but have far from the tightest tolarances. The ‘acool’ replacements are far superior seen as the smooth black ones installed in the pictures of the loop.

It takes some work once a year or so, but strangely custom water cooling does work, seldom, if ever, leak, yes actually work very well when cared for in this quite minimal way.