Here you’ll find a collection of things that I do, make, say and think. A collection of projects I publshare on other sites online. Including; custom built and designed guitar or Hi-Fi amplifiers and effects, custom PC servers, and rescued, upcycled hardware. Simply a central place to collect what I’m doing with some of my a creative rest at any given time.

If you are in search for my professional information go to >JohannesJohansson.com<

For multiple ways to contact me this >linktree< makes it easy.

Categories

- DIY (19)

- DIY Audio (10)

- DIY Computation (6)

- DIY Misc (4)

Random Posts

-

Splitter pedal: Two guitar amps at once

Splitting the output of your guitar/pedalboard to two separate Guitar Amps is one of the most powerful way in shaping your tone and ‘broaden’ the […]

-

Dumble Overdrive Special – Headshell

Head, strange word for this but is what it’s called, a head being the amplifier, presumably sitting on the ‘body’ represented by the stacks of […]

-

Turning laptops into mini-servers

One of the most common e-waste sources out there is laptops, slower than other computers and often not upgradable, lacking ability to change peripherals, like […]

-

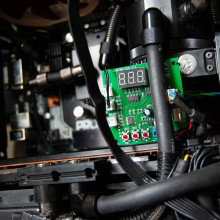

Restomod Car: Brakes and Suspension 1

Completely changing the suspension and brakes with oversized parts on this little car can make for a very fun ride and good companion to a […]

-

TrainWreck Rocket: 1. Redesigned

The trainwreck rocket is a highly coveted and copied guitar amp, however it, in part, is a copy itself. It is the core of a […]

Dumble Overdrive Special – Headshell

Head, strange word for this but is what it’s called, a head being the amplifier, presumably sitting on the ‘body’ represented by the stacks of speaker cabs. Using a schematic from the ampgarage.com forum as a base I set out to do some good and honest woodworking, always relaxing. First getting small pieces of 18mm plywood is no joke, I ended with an incredibly massive piece for the same cost as if I would have shopped where smaller pieces are sold. So I guess I’m building some more speaker cabinets from that next..

A quick box later, lots of sanding necessary, I noticed the plywood carried several empty pockets revealed when cut. As a result mixing up sawdust and woodglue creates a good putty 8f sorts to fill those gaps.

As most chassis available vary slightly in size its importent to tweak the measures to your specific one. Also keeping the ratios is important if you want the look to be the same of the original fumbles. Plenty of builds out there have off putting ratios that immediately signals a poor job.S

Some photos of the woodworking almost finished.

Happily the fit is good.

And so is the final case, glad of how it turned out. Although I’m sure I’ll revisit some minor details in the future it certainly is better than those custom orders availible on the market, with better hardware and hopefully durability.